Since 2002 in Shanghai, Linchen Tools has specialized in hard alloy saw blade tools. With advanced equipment and a focus on quality, it serves mold, automotive, electronics and more, committed to innovation and customer satisfaction.

Since 2002 in Shanghai, Linchen Tools has specialized in hard alloy saw blade tools. With advanced equipment and a focus on quality, it serves mold, automotive, electronics and more, committed to innovation and customer satisfaction.

Linchen Tools makes precision cutting efficient and reliable!

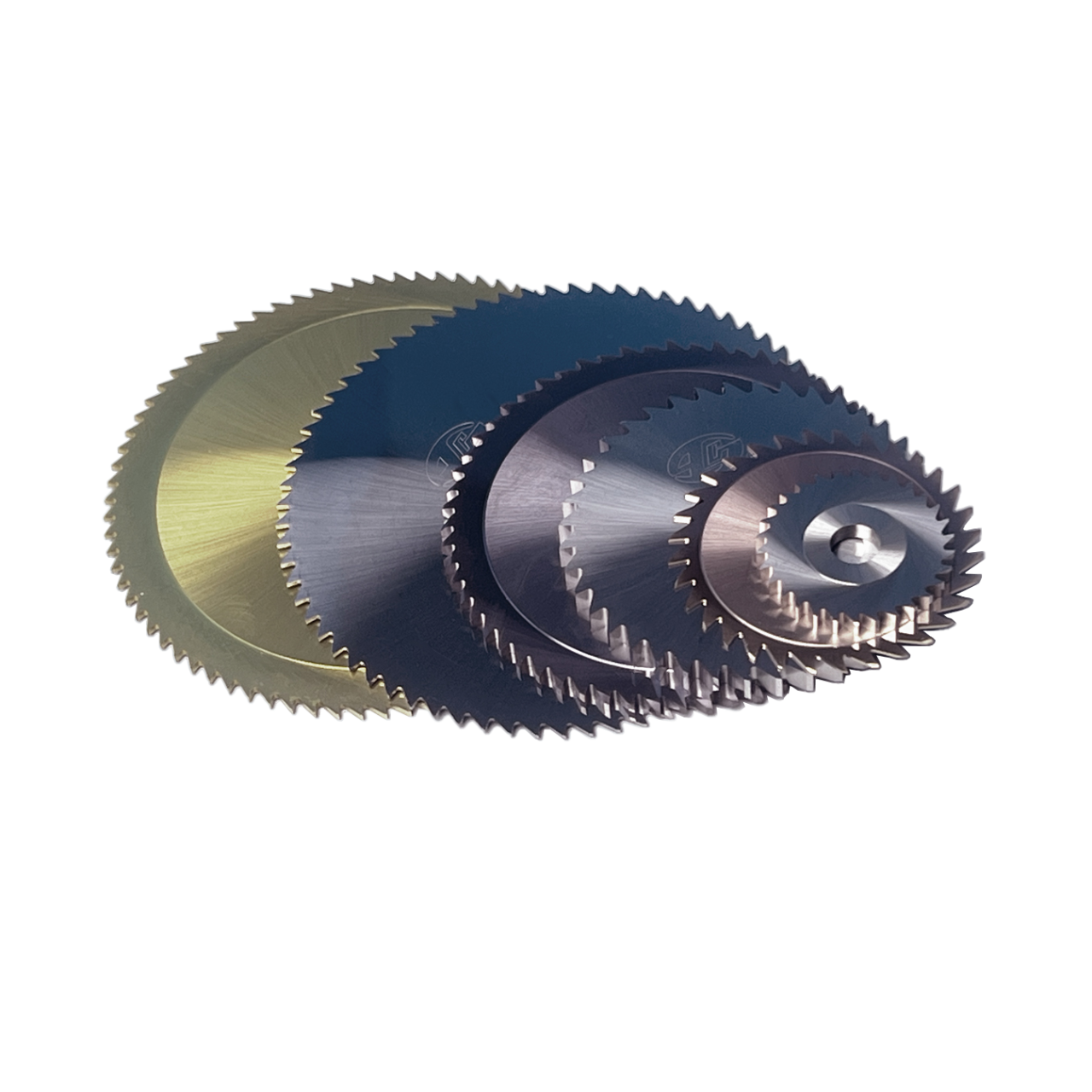

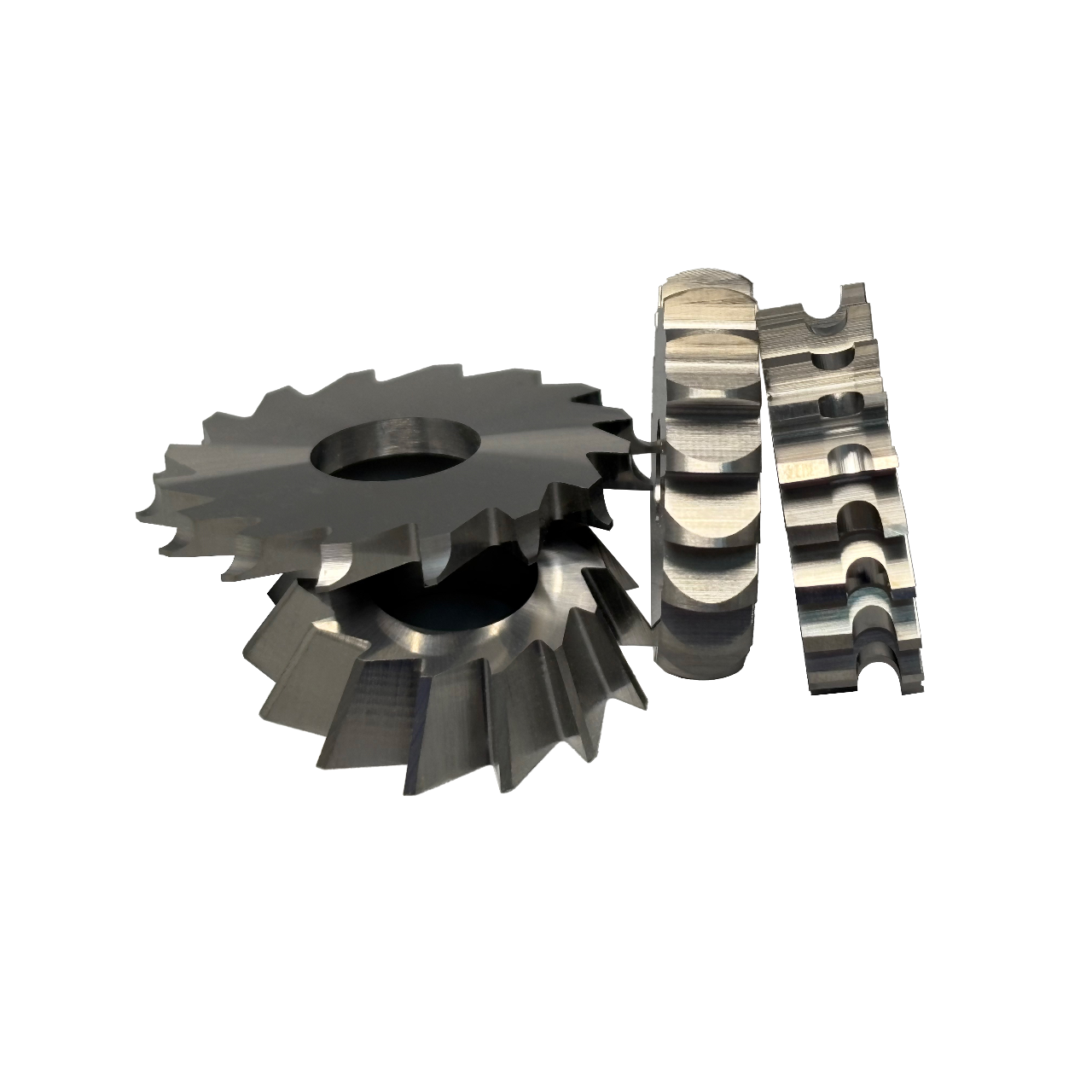

Linchen Tools specializes in hard alloy saw blade milling cutters and high-precision special-shaped tools. Our products are widely used in mold manufacturing, automotive components, electronics, and more. With advanced automation and a modern factory, we ensure top quality and competitive pricing, serving global partners with innovative solutions.

Unmatched Precision

Superior Quality

Trusted Excellence

– Linchen Tools’ carbide tools are designed for precision eyeglass frame and component processing.

– Suitable for cutting and shaping metal and high-hardness materials.

– Ensures smooth surfaces and accurate dimensions for frames and components.

– Meets the high standards of premium eyewear manufacturing

– Linchen Tools’ carbide tools efficiently process complex commutator grooves.

– Offers excellent wear resistance and machining stability.

– Ensures high precision and long service life for commutators.

– Widely used in the motor and power tool industries.

– Linchen Tools’ carbide tools are ideal for precision machining of automotive components.

– Efficiently processes engine, transmission, and braking system parts.

– Ensures dimensional accuracy and surface quality.

– Meets the automotive industry’s demand for high-performance tools.

– Linchen Tools’ carbide tools are designed for complex mold processing.

– Suitable for injection, stamping, and die-casting mold manufacturing.

– Delivers high-precision and high-efficiency machining solutions.

– Helps customers reduce production cycles and improve mold quality.

© 2025 SHANGHAI LINCHEN TOOLS CO., LTD.